Menu

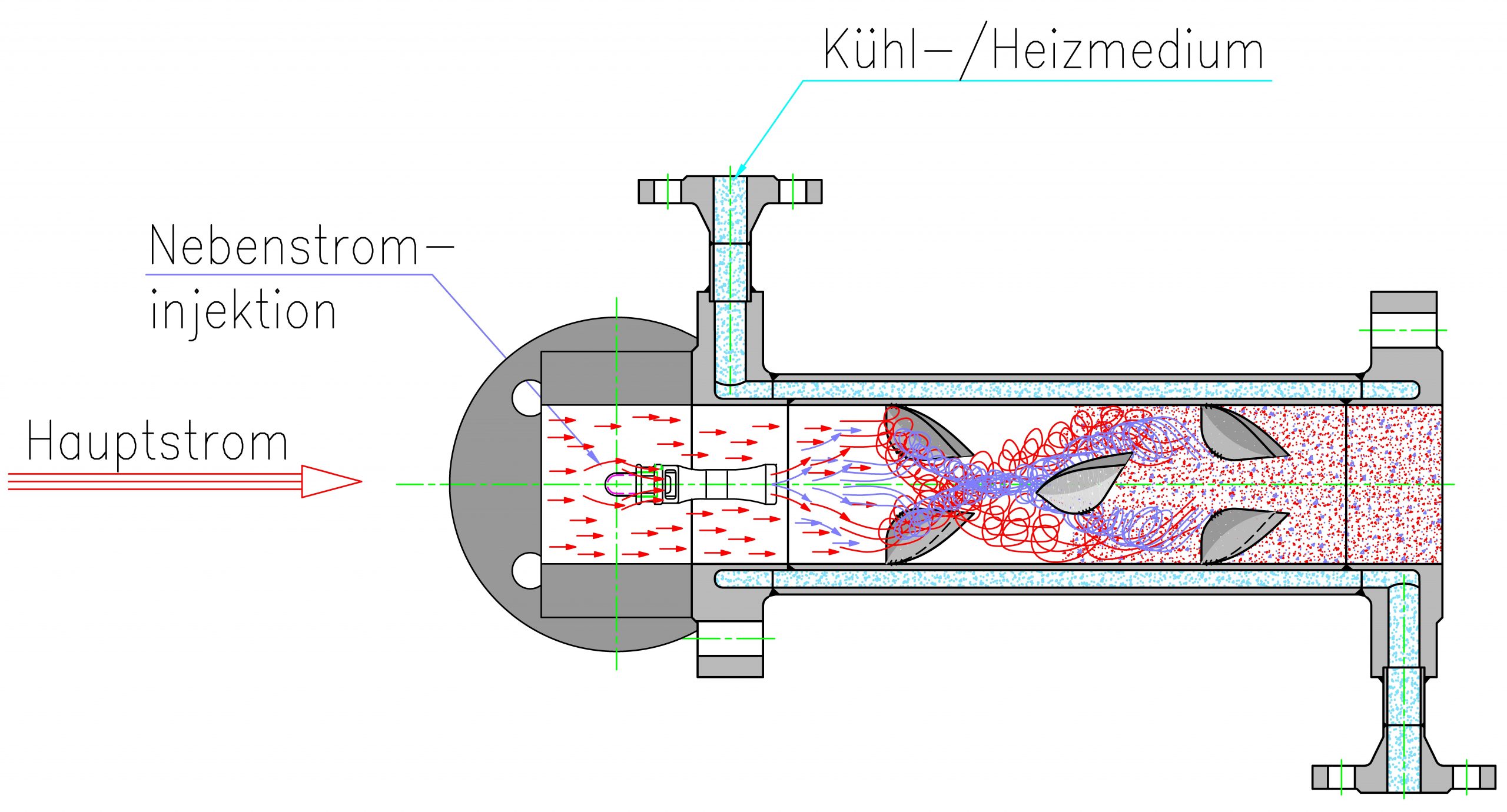

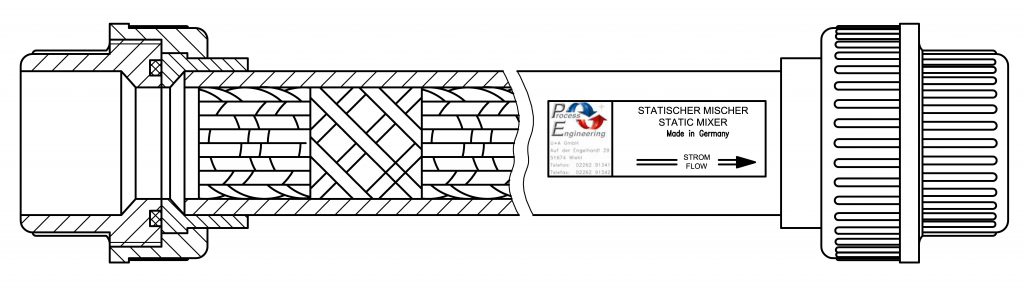

Static mixers from U+A are customized and are particularly characterized by their compact design, the absence of moving parts and the continuous operation.

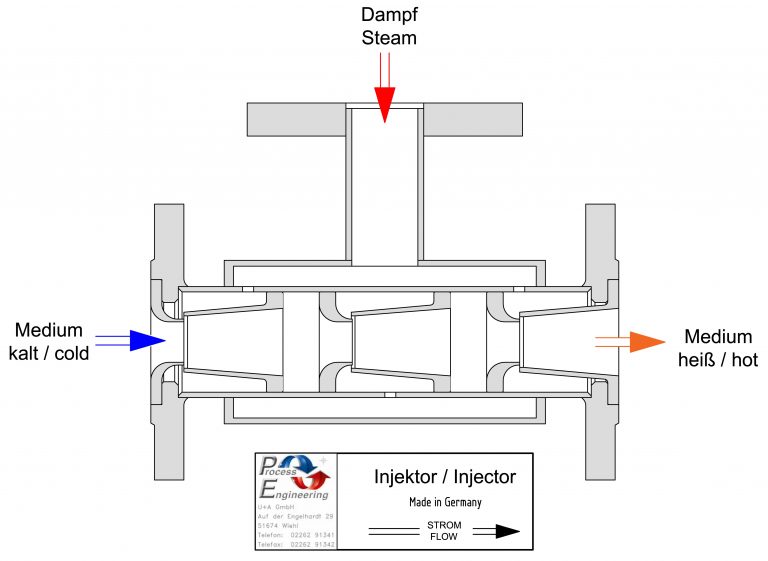

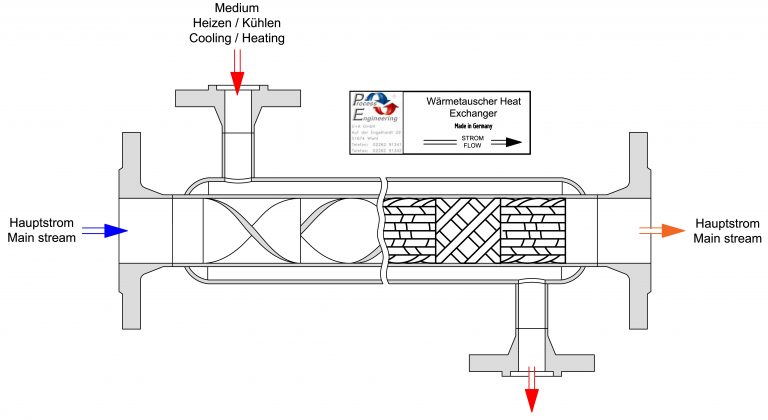

With their hygienic design, they offer very good mixing and homogenizing performance and are suitable for numerous tasks in the processing of food and pharmaceuticals in liquid, gaseous and solid form as well as for heat exchange.

They can be dimensioned for almost any volume flow, any density, viscosity and other specific product properties.

For this purpose, U + A has 18 different mixer types available, from helical mixers to non-clogging special designs as well as a large number of aseptic connections.

In connection with the surface-treated inner walls of the pipe and the possibility of soldering the mixing elements in the pipe without gaps, the formation of nests and gaps is almost impossible, so that product residues can be avoided. Thus reduces the cleaning effort to a minimum.

For particularly good visual control of the cleaning removable mixing elements are available.

Even the high requirements of the pharmaceutical industry can be met.

In the case of metallic materials, the permanently installed mixing elements can be welded in the pipe or alternativly soldered in the pipe without gaps by using nickel solder, this offers the advantage that there are no nests or gaps for the product to deposit.

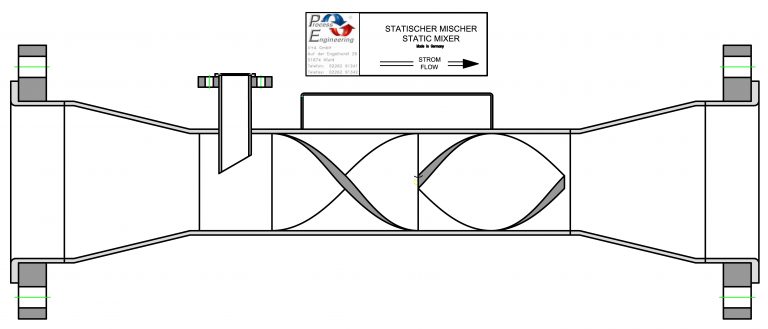

Removable elements are placed precisely in the pipe, so the operator has the option of removing the mixing elements for cleaning purposes.

Which installation variant is suitable for you depends on your application, we would be happy to advise you.

U + A is offering various designs of mixing elements.

The selection of the mixing elements and the required number depends on the mixing task.

As possible materials, we offer almost all available stainless steels and plastics in sizes 3 – 2500 mm.

Some standard forms are presented below.

Helical Mixing Elements ( the All-rounder) | Helical mixing elements are very suitable for the most applications.

The helical mixing elements generate, by the alternating arrangement of left-and right-handed mixing elements, a reversal of the rotation direction and a current division.

In the process the first mixing element generates two rotating vortices, which are performed simultaneously radially over the pipe cross section.

On impact with the following mixing element, the first two rotating vortices are splitted into two new vortices which are forced to rotate into the other direction.

This process is repeated until the desired homogeneity is reached.

With this type of mixer, the pressure loss is low in relation to the mixing quality.

The number of elements is calculated specifically for each application.

The installation options for these mixing elements are welded in, soldered using hard solder or removable. The cutting edges can be adapted to the application, so a dead space-free design is possible.

MV Mixing Elements (for fibrous and / or granular components) | The MV mixing elements from U + A are designed in such a way that there is practically no risk of clogging when there is a high proportion of fibrous and / or granular components flowing through them.

The individual mixing elements form tornado-like swirls which will be interwoven.

Thanks to these excellent properties, it is possible to mix in all kinds of dosing chemicals within a very short time.

SW Mixing Elements ( special helix mixer) | The advatages of the SW Mixing Elements are similar to those of the conventional helix mixer. These mixing elements can also be designed to be permanently integrated or removable. In order to increase the mixing performance with the same design, other changes to the geometry can be made.

PEW mixer (for emulsions or for liquid – gas – dispersion) | The PEW mixing elements are best suited for the production of emulsions or gas-liquid dispersion. The ceramic material used is suitable for most aggressive media. This material is also well suited at high temperatures (for example in exhaust gas cleaning).

All Mixing – Elements are manufactured specifically for the application.

Production takes place in Germany in order to keep delivery times short and to be able to react quickly to changing customer needs.

Alternatively, the enquiry form can be downloaded as a PDF.

Alternatively, the enquiry form can be downloaded as a PDF.

Alternatively, the enquiry form can be downloaded as a PDF.