Your specialist for static mixers, injectors and heat exchangers

IT'S THE MIX THAT MAKES IT

Mixing technologies for:

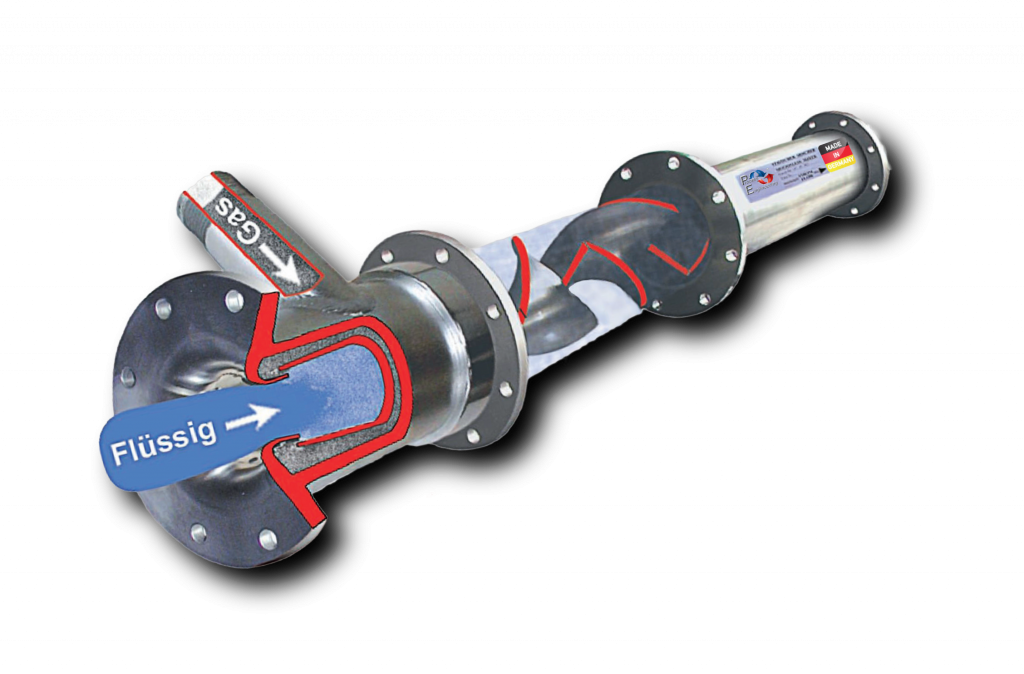

- liquid / liquid

- liquid / gaseous

- gaseous / gaseous

- liquid / solid

- solid / solid

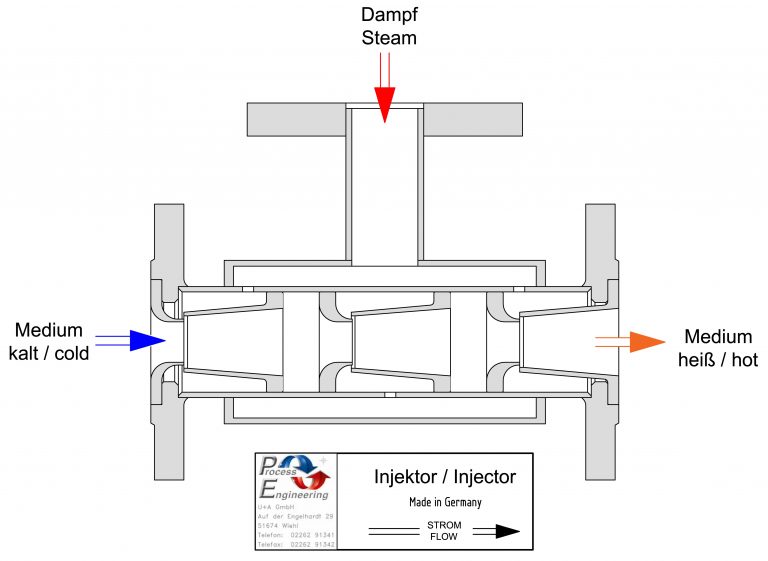

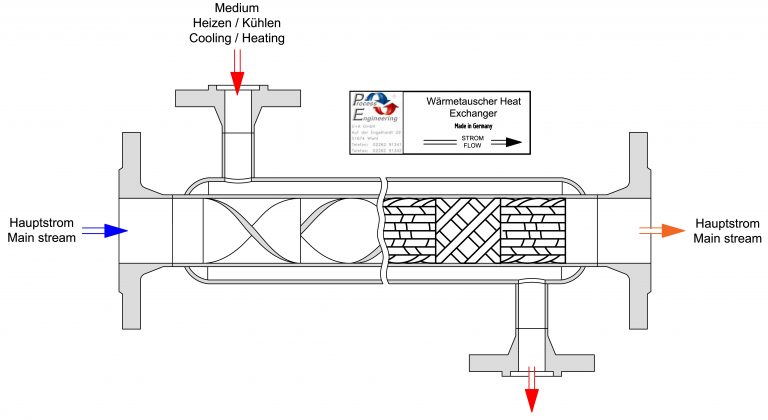

- heat exchange

Mixing technologies for:

Self-cleaning design possible due to the dead space-free design U & A Process Engineering GmbH manufactures static mixers, injectors and special heat exchangers in Germany, develops new technologies and delivers to well-known companies worldwide.

Our devices are made according to customer requirements and can be offered in almost all available stainless steels and plastics in sizes 3 – 2500 mm.

With over 28 years of experience and the resulting know-how, we ensure the integration of our devices into your system. Since each of our products is individually adapted to the needs of the customer, we are constantly looking for new solutions for the benefit of our customers. In order to achieve this, we also support our customers after delivery. In a profit-conscious world, we are constantly striving to increase productivity, whereby all required tests are conscientiously carried out and documented.

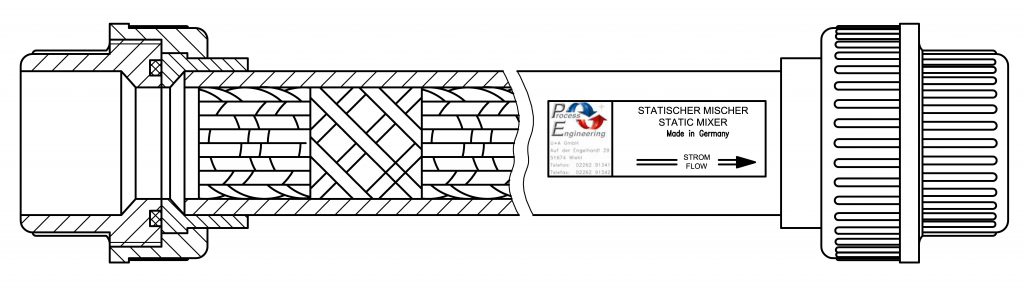

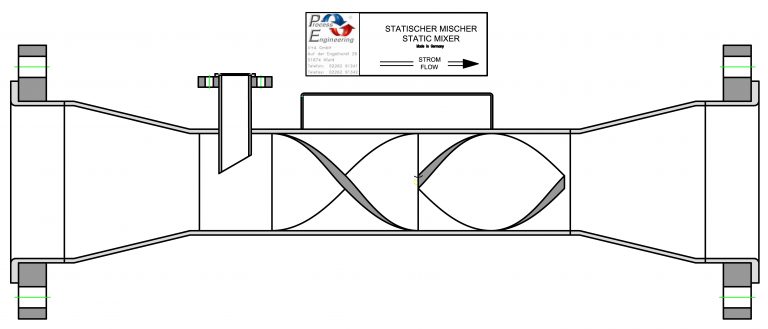

The static mixer, which has no moving parts, is working maintenance-free and very energy-efficient, makes a significant contribution to keeping operating costs low and thereby improving profitability.

The static mixer created by U&A Process Engineering is the modern alternative to traditional dynamic and powered container systems.

By using this type of mixing technology, many advantages can be realized in all branches of industry.

As we are constantly searching for improvements, we have also invented a new form of mixer geometry.

The special feature of the newly developed mixing elements is the additional function of the inclusion of openings on each mixing element between the two flow chambers, which convey part of the flow radially from one flow chamber to the other by means of flow guiding plates of differing geometries. The size and flow speed of the radially guided partial flow can be set to the respective mixing task and is generated twice on each mixing element, once from the right-hand flow chamber to the left, and once in the reverse direction.

This construction also ensures outstanding homogeneity results with a comparatively low loss of pressure even with the lowest flow speeds and highly viscous product flows.

In addition, the mixing elements are designed without clearance volume in a

polished version for use in sterile areas and are easy to clean.

Smaller droplet diameters in the production of liquid/liquid dispersions.

Smaller bubble diameters in the production of gas/liquid dispersions.

Design as heat exchanger for the heating or cooling of highly viscous, temperature-sensitive product flows.

These mixing elements are suitable for installation in round and rectangular cross-sections and can be manufactured from all high-grade steels and synthetic materials.

Would you like us to call you back or do you have a question about our products? Please fill out the form and we will get back to you.

You can send special product enquiries using the forms on the product pages.

Alternatively, the enquiry form can be downloaded as a PDF.

Alternatively, the enquiry form can be downloaded as a PDF.

Alternatively, the enquiry form can be downloaded as a PDF.