Menu

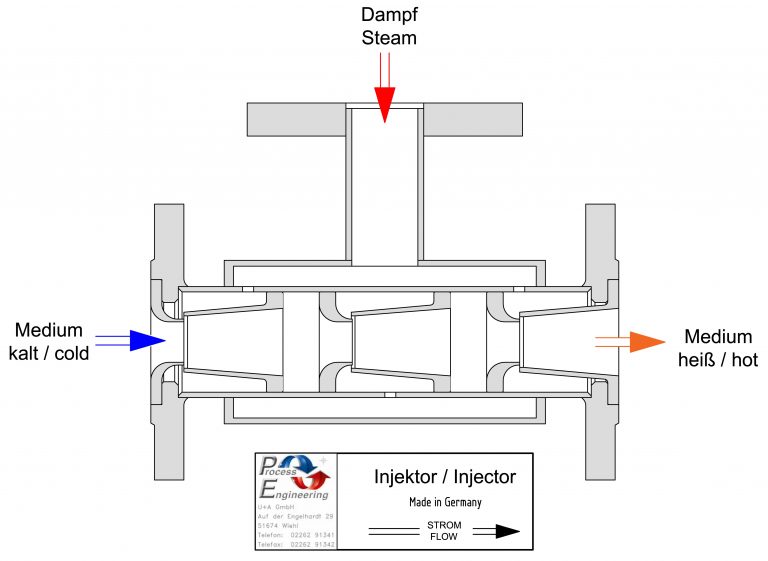

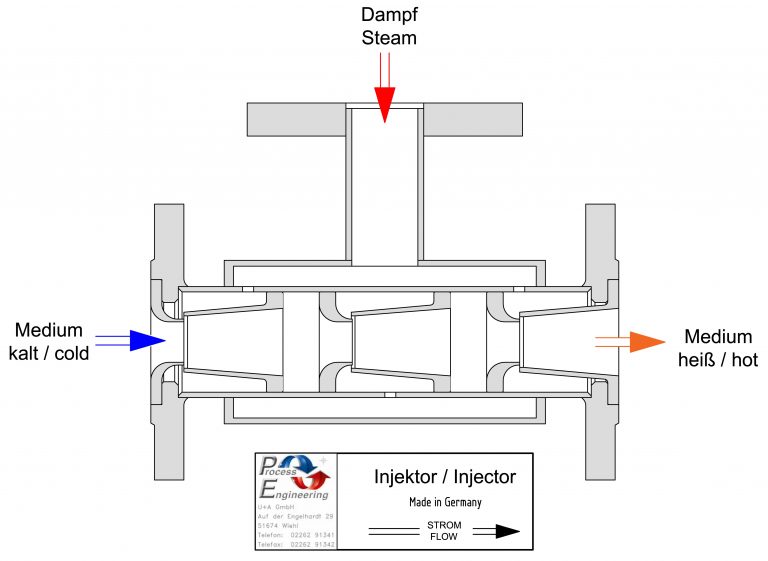

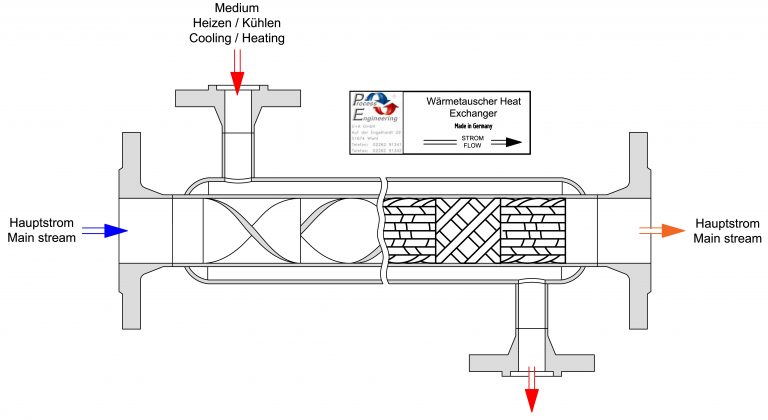

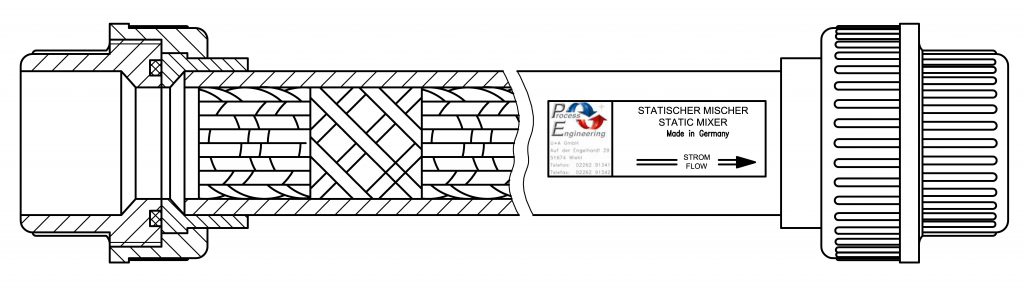

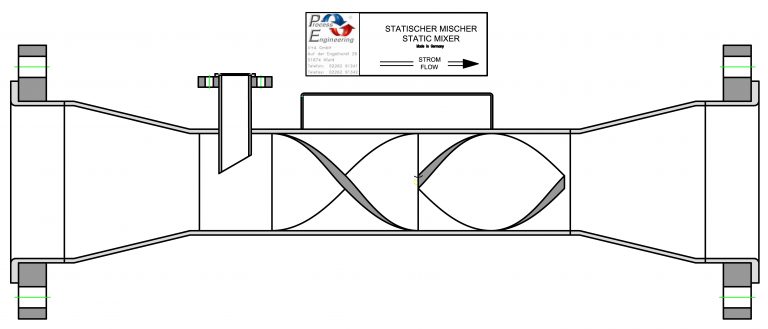

We supply our Static Mixers, Heat Exchangers and Injectors in practically all obtainable precious metals and plastics in nominal widths between DN 3 and DN 2500 mm.

Production:

Our products are manufactured in accordance with customer requirements at the facilities of our highly qualified contract partners in Germany with the following production authorisations: DIN ISO 9001, DGRL 97/23/EG, WHG § 19, AD-HP 0, Bureau Veritas, Germanic Lloyd, ÖN M 7812, § 14, BGBI Pressure Vessel Code, China Stamp, U Stamp, U2 Stamp, Det Norske Veritas. Almost no limits are set to other requirements.

DGRL, AD, TRB, TRD, TÜV, ASTM, TEMA, BS, Stoomwezen and others.

Hydro, Nekal, Frigen, Helium and others

Ultrasound (subsonic), magnetic powder, colour penetration, x-ray test as well as special tests.

Zirconium, Titanium, Hastelloys, Incoloys, and Inconels and others.

This enables us to meet the highest quality and testing requirements. The manufacturing can be carried out accorsing to customers spacifications in any case.

Send us your request with your technical requirements,

our specification data sheet will support you.

We look forward to your inquiries and remain, with best regards

Alternativ kann das Anfrageformular als PDF heruntergeladen werden.

Alternatively, the enquiry form can be downloaded as a PDF.

Alternatively, the enquiry form can be downloaded as a PDF.

Alternatively, the enquiry form can be downloaded as a PDF.