Menu

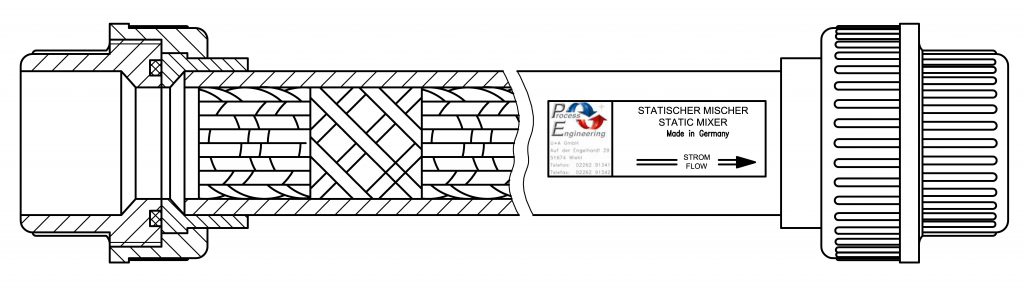

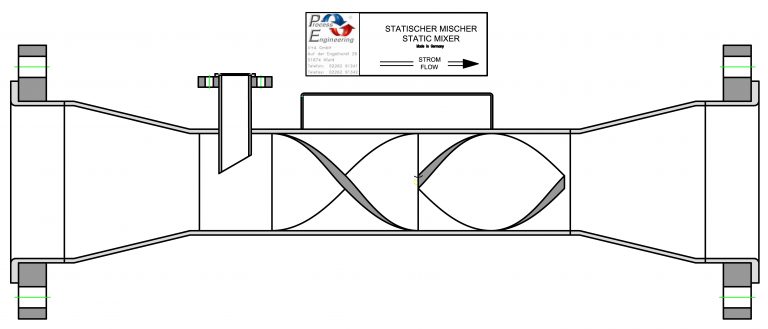

Static mixers from U+A are customized and are particularly characterized by their compact design, the absence of moving parts and the continuous operation.

With their hygienic design, they offer very good mixing and homogenizing performance and are suitable for numerous tasks in the processing of food and pharmaceuticals in liquid, gaseous and solid form as well as for heat exchange.

They can be dimensioned for almost any volume flow, any density, viscosity and other specific product properties.

For this purpose, U + A has 18 different mixer types available, from helical mixers to non-clogging special designs as well as a large number of aseptic connections.

In connection with the surface-treated inner walls of the pipe and the possibility of soldering the mixing elements in the pipe without gaps, the formation of nests and gaps is almost impossible, so that product residues can be avoided. Thus reduces the cleaning effort to a minimum.

For particularly good visual control of the cleaning removable mixing elements are available.

Even the high requirements of the pharmaceutical industry can be met.

Materials | Almost all steels, stainless steels and plastics can be used as materials. Whether the material is chosen based on the selection of the remaining system or whether it has to have certain resistances, the mixer can in principle be manufactured in the same material.

The steel version includes, for example:

H II, St 37, St 55, DIN 1.4571, 1.4541, 1.4535, AISI 316L, 304L, Titanium, Zirconium, Hastelloy, Monel

Plastic version for example in: PVC, PP, HDPE, PVDF, PTFE

In addition, mixer housings made of steel or GRP can be provided with linings made of PTFE, PVDF, PFA, PP, PVC or PE in order to combine chemical resistance with mechanical resistance

Surfaces | The surfaces of the pipe inner walls as well as the individual mixing elements can be delivered in different qualities.

Pipe inner walls: honed or lapped

Mixing elements: mechanically polished, electropolished

Over 25 years U+A is offering static mixers made of steel with lining for specific operating conditions which makes the use of particularly resistant materials necessary.

All parts of our static mixers which are in contact to the medium are designed to be corrosion-resistant. In the case of lined static mixers, only the lining is made of high-quality material and therefore this design has mainly economic benefits. For example: Compared to a static mixer made of Hastelloy a PFTE lined static mixer can reduce the acquisition cost about 50%.

Depending on the application, nickel-based materials or plastics are also available.

The selection of the suitable lining depends on the application.

PTFE, PVDF, PFA, PP, PVC and PE are available for the lining and steel, stainless steel or GRP pipes with the desired connections are available for the pipe part.

Examples of applications are: Use cases in the aggressive and / or corrosive media such as boiling amyl acetate, concentrated sulfuric or nitric acid, toluene, fluorine, chlorine or bromine are to be conveyed and mixed.

Areas of application are for example: Pickling plants when mixing the pickling solutions and their subsequent reprocessing or to adjust the pH value of process water if the dosage of aggressive chemicals is required.

The lined static mixer is also enjoying increasing popularity in the food and paint industry , because of the low adhesion of the media to PTFE. Color pigments or additives can be mixed in inline and the cleaning effort when changing batches or starting shifts is reduced to a minimum, so that not only the result remains constant, but productivity is also increased

For the generation of small gas bubble diameters in liquids, U + A Process Engineering GmbH offers an economically and process-technically interesting solution consisting of a combination of static mixer and injector.

This combination improves the quality of the dispersion even with fluctuating volume flow.

Since both devices do not contain any moving parts, they are durable and easy to clean.

The combination will be specifically designed for each application.

As possible materials we offer almost all available stainless steels and plastics in sizes DN 15 – DN 2000.

Especially for the food and pharmaceutical industries, we also offer mixers and injectors in nickel-soldered or polished versions.

For the entry of small amounts of gas | U + A offers a combination in which the gas is metered directly into the main flow through an upstream injector or a lance system with an injector.

Tests have shown that gas bubble diameters smaller than 1 mm can be generated in the injector. The downstream static mixer has the task of further reducing the size of the gas bubbles, preventing their growth, creating reaction time and optimizing the distribution in the medium. As the flow rate increases, the bubble diameter decreases and the reaction area increases.

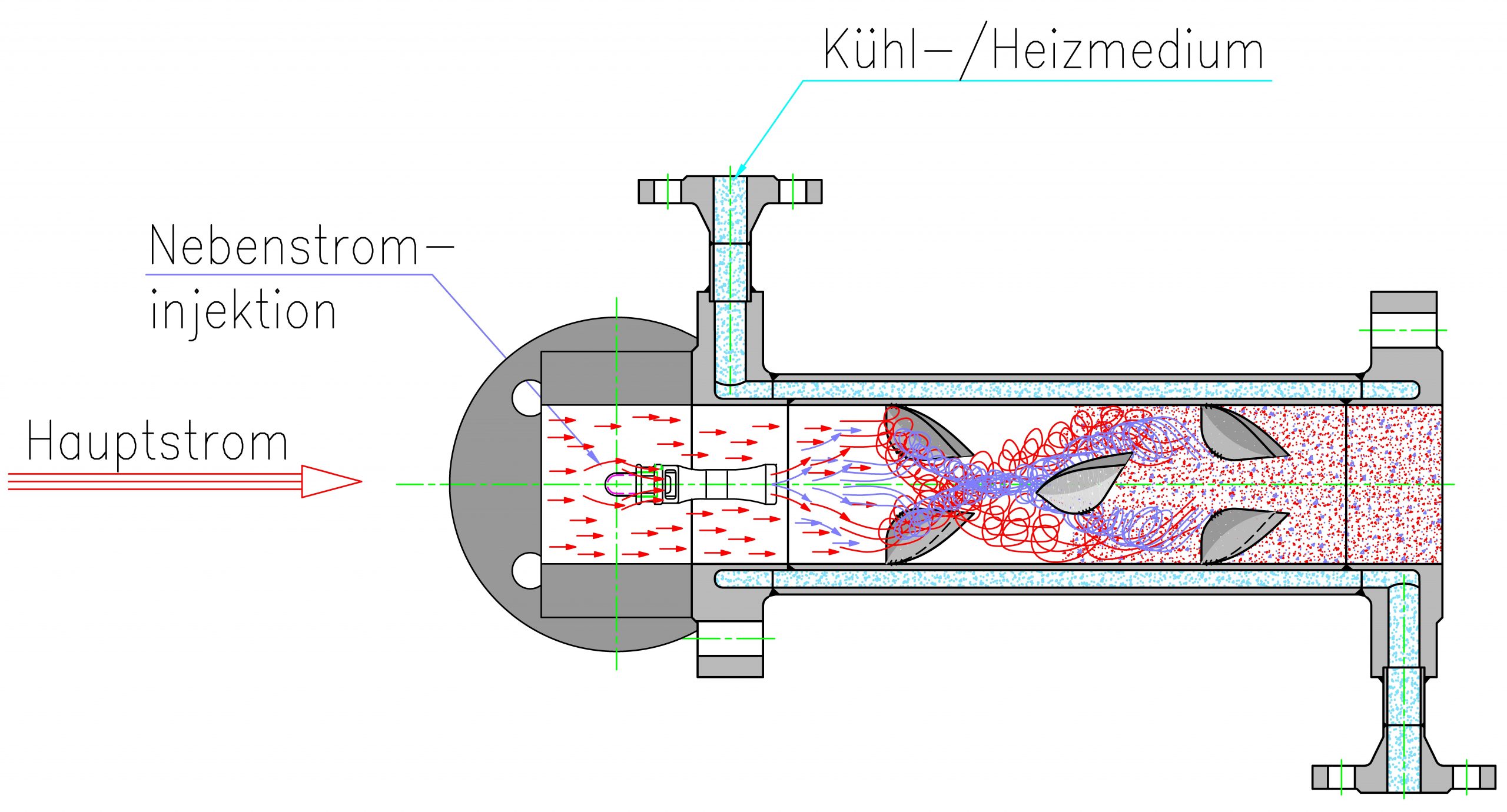

For the entry of large amounts of gas | U + A offers a complete dispersing system.

This consists of a main mixer, a bypass pump, a Venturi injector and a premixer.

In this system, a bypass pump takes a bypass flow from the main flow, which sucks in the gas by means of the venturi injector and premixes it in the premixer. After this process, the mixture is fed to the main flow mixer, where it is mixed further. So the gas-liquid reaction can be completed.

The above versions offer many possible uses, for example in the ozone treatment of swimming pool water, the entry of oxygen in biotechnology, drinking water purification or for chemical reaction technology. Here in particular, toxic, reactive and expensive gases are often used, the consumption of which must be kept as low as possible for reasons of cost.

We supply our Static Mixers, Heat Exchangers and Injectors in practically all obtainable precious metals and plastics in nominal widths between DN 3 and DN 2500 mm.

Production:

Our products are manufactured in accordance with customer requirements at the facilities of our highly qualified contract partners in Germany with the following production authorisations: DIN ISO 9001, DGRL 97/23/EG, WHG § 19, AD-HP 0, Bureau Veritas, Germanic Lloyd, ÖN M 7812, § 14, BGBI Pressure Vessel Code, China Stamp, U Stamp, U2 Stamp, Det Norske Veritas. Almost no limits are set to other requirements.

DGRL, AD, TRB, TRD, TÜV, ASTM, TEMA, BS, Stoomwezen and others.

Hydro, Nekal, Frigen, Helium and others

Ultrasound (subsonic), magnetic powder, colour penetration, x-ray test as well as special tests.

Zirconium, Titanium, Hastelloys, Incoloys, and Inconels and others.

This enables us to meet the highest quality and testing requirements. The manufacturing can be carried out accorsing to customers spacifications in any case.

Send us your request with your technical requirements,

our specification data sheet will support you.

We look forward to your inquiries and remain, with best regards

U + A is offering various designs of mixing elements.

The selection of the mixing elements and the required number depends on the mixing task.

As possible materials, we offer almost all available stainless steels and plastics in sizes 3 – 2500 mm.

Some standard forms are presented below.

Helical Mixing Elements ( the All-rounder) | Helical mixing elements are very suitable for the most applications.

The helical mixing elements generate, by the alternating arrangement of left-and right-handed mixing elements, a reversal of the rotation direction and a current division.

In the process the first mixing element generates two rotating vortices, which are performed simultaneously radially over the pipe cross section.

On impact with the following mixing element, the first two rotating vortices are splitted into two new vortices which are forced to rotate into the other direction.

This process is repeated until the desired homogeneity is reached.

With this type of mixer, the pressure loss is low in relation to the mixing quality.

The number of elements is calculated specifically for each application.

The installation options for these mixing elements are welded in, soldered using hard solder or removable. The cutting edges can be adapted to the application, so a dead space-free design is possible.

MV Mixing Elements (for fibrous and / or granular components) | The MV mixing elements from U + A are designed in such a way that there is practically no risk of clogging when there is a high proportion of fibrous and / or granular components flowing through them.

The individual mixing elements form tornado-like swirls which will be interwoven.

Thanks to these excellent properties, it is possible to mix in all kinds of dosing chemicals within a very short time.

SW Mixing Elements ( special helix mixer) | The advatages of the SW Mixing Elements are similar to those of the conventional helix mixer. These mixing elements can also be designed to be permanently integrated or removable. In order to increase the mixing performance with the same design, other changes to the geometry can be made.

PEW mixer (for emulsions or for liquid – gas – dispersion) | The PEW mixing elements are best suited for the production of emulsions or gas-liquid dispersion. The ceramic material used is suitable for most aggressive media. This material is also well suited at high temperatures (for example in exhaust gas cleaning).

All Mixing – Elements are manufactured specifically for the application.

Production takes place in Germany in order to keep delivery times short and to be able to react quickly to changing customer needs.

In the case of metallic materials, the permanently installed mixing elements can be welded in the pipe or alternativly soldered in the pipe without gaps by using nickel solder, this offers the advantage that there are no nests or gaps for the product to deposit.

Removable elements are placed precisely in the pipe, so the operator has the option of removing the mixing elements for cleaning purposes.

Which installation variant is suitable for you depends on your application, we would be happy to advise you.

As the customer’s wishes are our top priority, we manufacture our mixers in almost all desired materials. Whether the material selection focuses on chemical or corrosive resistance or whether the mixer should also fit perfectly into the existing pipeline in terms of appearance. There are almost no limits to the choice of material. In the field of plastics, we manufacture e.g. from PVC, PP, PE, GRP etc. and in the field of metallic materials from e.g. H II, St 37, St55, 1.4571, 1.4541, 1.4535, AISI 316L, 304L, titanium, zirconium, Hastelloy, Monel etc. In addition, we offer our mixers with various coatings, such as PTFE or PVDF, in order to be able to selectively counteract corrosive or chemical influences.

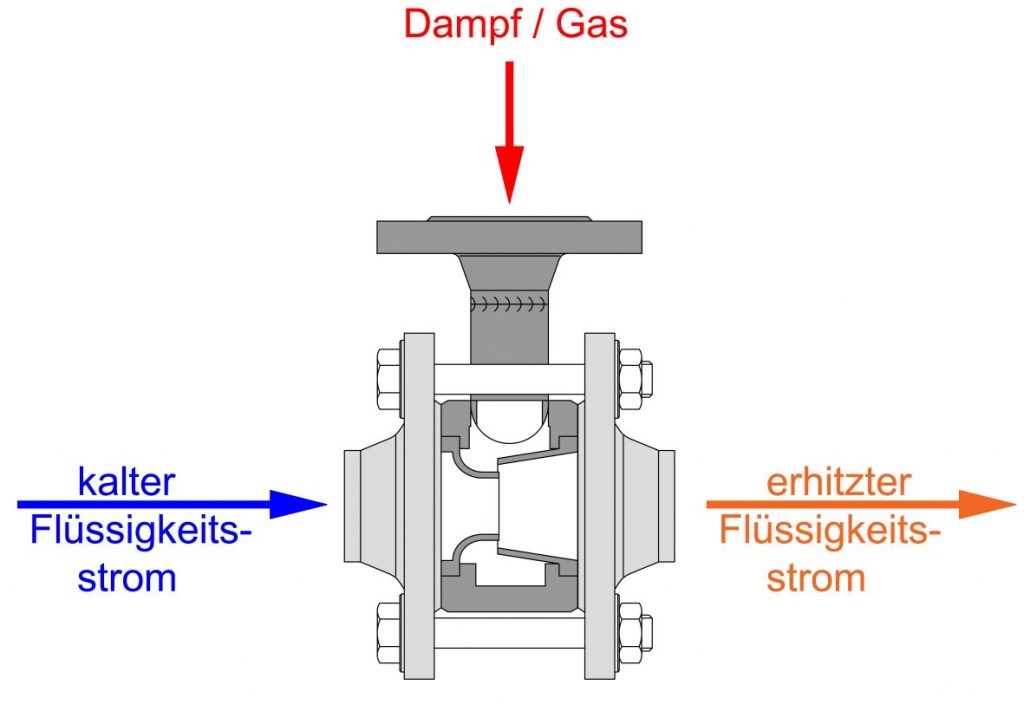

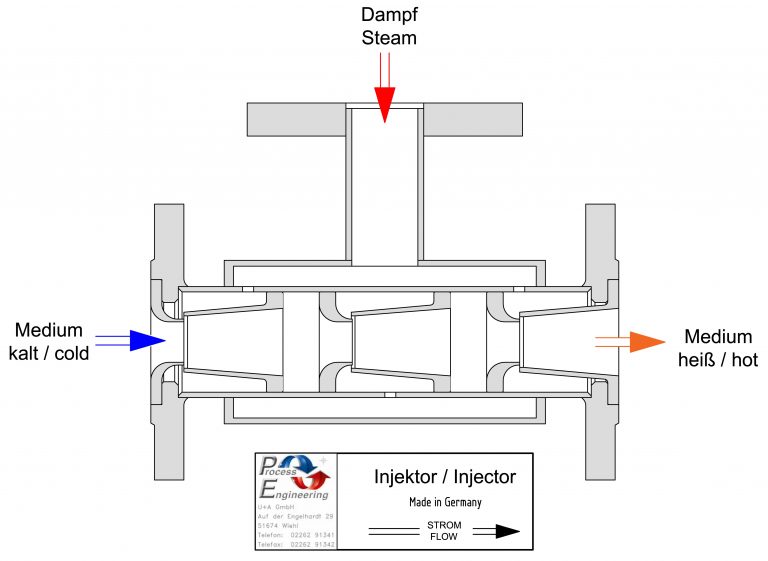

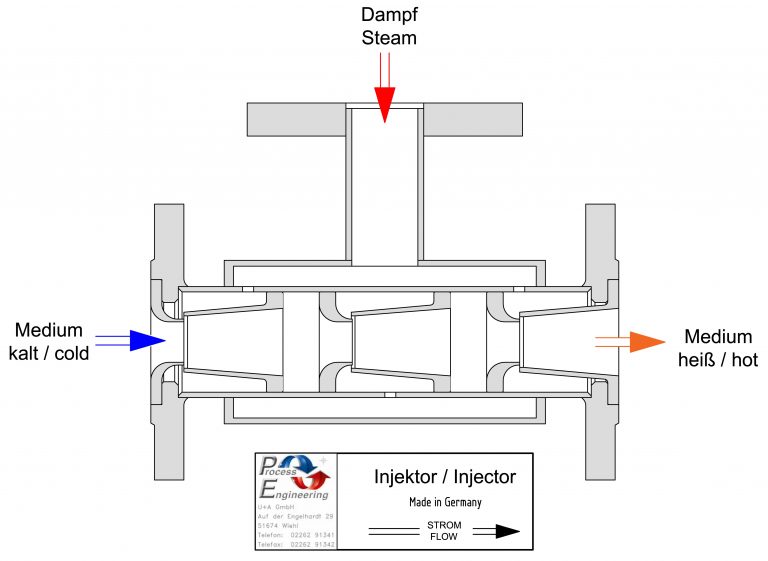

U + A steam injectors have been in use for years to heat up product cycles. The medium is heated in the flow and the desired temperature can be reached quickly and safely. The steam injector can be easily integrated into an existing pipeline and can be offered with all connection options.

The heart of the U+A injector is a Venturi nozzle in which the medium to be heated is accelerated. A cone formed counterpart is designed in such a way that an annular gap is created. The steam is introduced tangentially into the outer casing, passes through the annular gap onto the medium to be heated and condenses. This condensation ensures even heating, whereby the noises caused by vapor bubble implosions are reduced to a minimum.

The heart of the U+A injector is a Venturi nozzle in which the medium to be heated is accelerated. A cone formed counterpart is designed in such a way that an annular gap is created. The steam is introduced tangentially into the outer casing, passes through the annular gap onto the medium to be heated and condenses. This condensation ensures even heating, whereby the noises caused by vapor bubble implosions are reduced to a minimum.

In this way, a low-noise energy input (normally approx. 75 dB) can be achieved. In general, the amount of steam can be regulated from 0 – 100%. Maximum heat transfer with a small size and investment costs is achieved in this way.

• No moving parts

• Low maintenance

• Can be easily retrofitted in existing systems

• Can be installed in almost all environments

• Quick and easy commissioning

• low-noise steam supply

• Steam quantities adjustable 0 – 100%

• maximum heat transfer

• minimal pressure loss

• favorable installation dimensions

• Any installation position

• Can also be used inside containers with a stirrer effect

• Long service life with a suitable choice of material

• Can be made from a wide variety of materials

• Relatively low acquisition costs

• Simple and reliable

Further possible uses of our injectors are the hot water station for rapid heating of a product stream in the pipeline in one pass and the installation as a liquid jet mixer into a container.

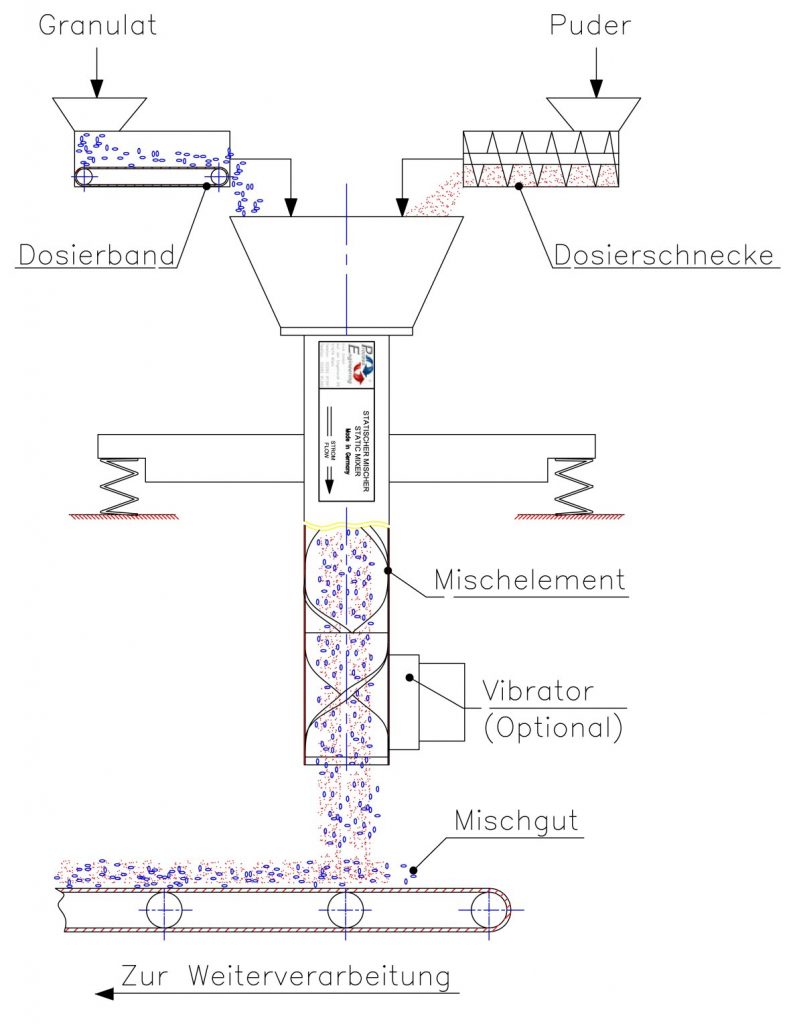

The static solids mixer from U+A Process Engineering GmbH offers an economically and process-technically interesting solution for the gentle homogenization of free-flowing solids such as grains, foodstuffs, granules, color pigments, types of powder and much more. With this static mixer, almost all free-flowing solids can be mixed together.

The solids mixer guarantees consistent mixing quality in free fall without a motor drive.

Since it has no moving parts, it is practically maintenance-free with a very high level of production reliability.

Existing systems can be upgraded with reasonable effort, since the construction is compact and the installation height is low.

The solids mixers are specifically designed for each individual customer application.

As possible materials we offer almost all available stainless steels and plastics in sizes DN 15 – DN 2000 .

Especially for the food and pharmaceutical industries the mixers can also be manufactured in a nickel-soldered, polished or coated design.

The static solid mixers from U+A Process Engineering GmbH are installed vertically and charged with the components to be mixed via one or more dosing systems.

The functional principle of the solids mixer follows that of our helical static mixers, in which the individual helix mixing elements are offset from one another by 90 °.

The helical mixing elements generate, by the alternating arrangement of left-and right-handed mixing elements, a reversal of the rotation direction and a current division.

In the process the first mixing element generates two rotating vortices, which are performed simultaneously radially over the pipe cross section.

On impact with the following mixing element, the first two rotating vortices are splitted into two new vortices which are forced to rotate into the other direction.This process is repeated until the desired homogeneity is reached.

Due to the design, this type of construction guarantees radial flow conduction over the pipe cross-section and thus satisfactory mixing results even at low flow velocities. In this way, mixtures with very different proportions (mixing ratios> 1: 1000) of the individual components can be implemented in the finished mixture.

As standard, the mixers are made of stainless steel, but all suitable plastics or special materials can also be used if required. For products where sticking or agglomeration is conceivable, a vibration module can be integrated as a remedy.

The areas of application are in plastics production for mixing different granulates, adding masterbatches, regranulates or other polymers, or very small amounts of additives required for further processing.

In the food industry, the applications are in the mixing of different solids of all kinds. On the one hand, candies of different flavors and colors or chocolate buttons, on the other hand, the ingredients of ready meals and ceral mixes are mixed before preparation. In these applications, different requirements are always placed on the mixer, which, however, are met by a suitable design.

Furthermore, static solid mixers have proven themselves in the agricultural industry (mixing of seeds etc.) and in the building materials industry for any powdery mixtures (for example admixture of color pigments, additives and additives) because of the consistent mixing quality and high production reliability.

The typical applications are in all areas in which constant mixing is required in-line; here, due to the further development of the mixing elements, a constant throughput is not necessary.

The following advantages should be mentioned:

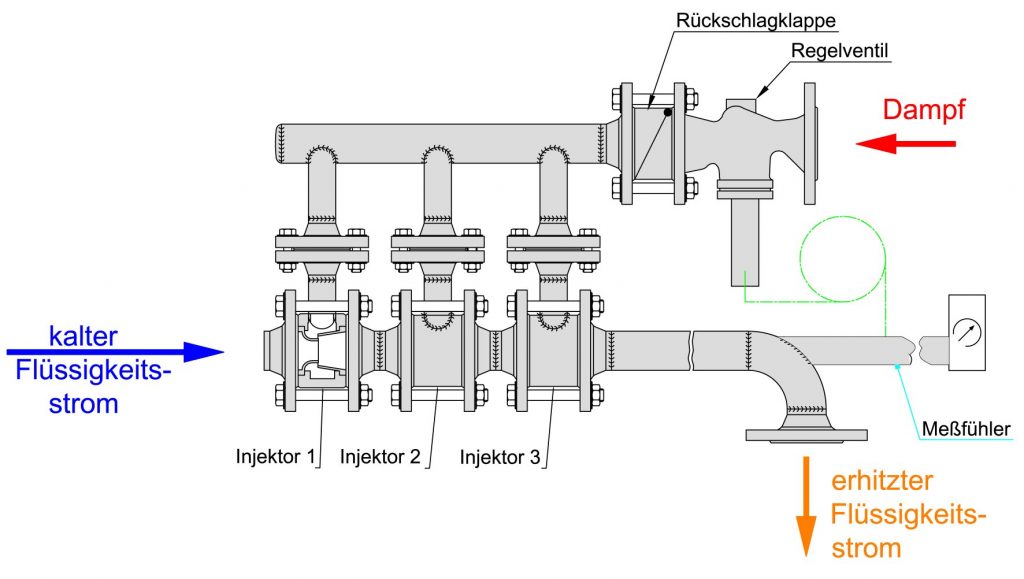

Our hot water station is recommended wherever a product flow in a pipeline needs to be heated as much as possible within the shortest possible time.

U + A offers these customer-specific with a defined scope of services and complete control equipment with and without auxiliary energy.

The hot water station consists of several steam injectors, a control thermostat, a control valve with or without auxiliary energy as well as the necessary connections.

The hot water station is available as a complete unit up to a nominal diameter of 250 mm, but custom-made products are possible.

After being installed in the system, the assembly without auxiliary energy works completely independently and does not depend on an external energy supply.

Despite the designation “hot water station”, of course other suitable media can also be heated. The number and size of the steam injectors is determined individually depending on the requirements with regard to the flow rate and the temperature to be achieved.

By connecting the hot water station to the control device, the temperature to be reached can be set precisely, up to approx 220°C.

The version without auxiliary energy results in further advantages, since the control thermostat and the control valve work without auxiliary energy, there is no risk of influencing the measured values, for example through voltage peaks. There is also no need for expensive and, especially at high temperatures, susceptible cabling to control cabinets.

Cast materials and stainless steels are used for the control device. The steam injectors are made of steel or stainless steel. Other materials, such as Hasteloy, PTFE and nickel can be used if necessary. For abrasive media, the trim can be enamelled or provided with particularly suitable special coatings.

Due to the low follow-up costs, investments in steam injectors or hot water stations pay for themselves much faster than other methods.

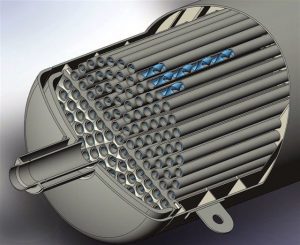

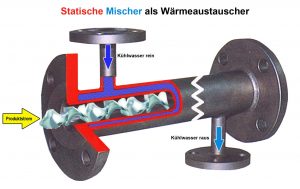

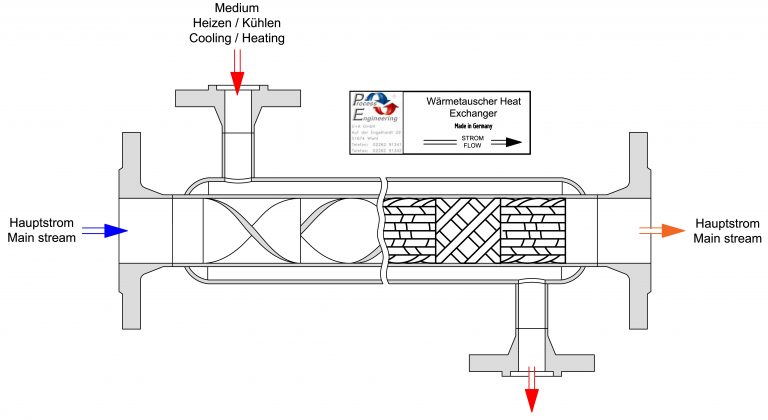

Operation of U+A Heat Exchangers

Our tube bundle or double-tube heat exchanger are equipped with static mixing elements, for thermal gentle heat treatment of highly viscous liquids.

This equipping of the heat exchanger results in significant advantages:

The performance of the heat transfer can be increased up to 6-fold compared to a conventional heat exchanger.

The product flow is moved from the pipe wall to the center of the pipe by the radial flow of the spiral mixing elements. In addition, each of the mixing elements divides the current and reverses the direction of rotation whereby a product-friendly heat transfer with simultaneous homogenization is achieved. Temperature and flow gradients are reduced.

A consistent quality of the end product is guaranteed in this way.

The retrofitting of existing heat exchangers with static mixers is also possible without any problems, because the mixing elements are available in welded, brazed or removable versions.

By retrofitting existing heat exchanger with static mixing elements chains, the heat exchanger capacity may be increased. Product damage on the tube inner wall can be avoided. The use of higher temperatures of the heating medium is now possible.

Advantagers of U + A Heat Exchangers

1. Up to 6-fold increase in performance of heat transfer

2. Easy cleaning thanks to removable mixing elements.

3. Mixing elements can also be adapted to sensitive media

4. Maintenance-free and low wear, because there are no moving parts

5. Easy retrofit into existing systems

Alternativ kann das Anfrageformular als PDF heruntergeladen werden.

Alternatively, the enquiry form can be downloaded as a PDF.

Alternatively, the enquiry form can be downloaded as a PDF.

Alternatively, the enquiry form can be downloaded as a PDF.