Menu

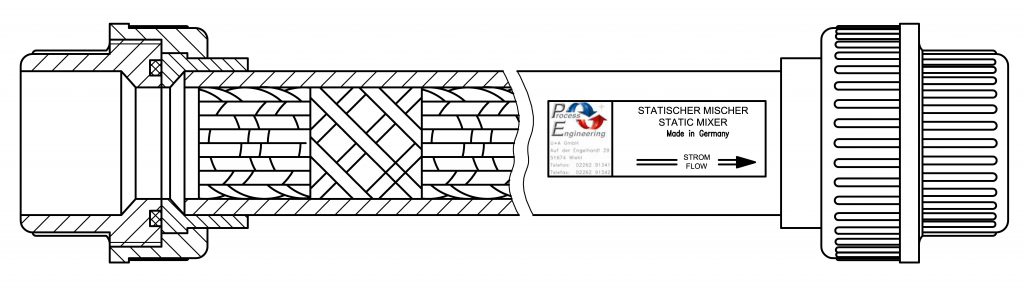

U + A steam injectors have been in use for years to heat up product cycles. The medium is heated in the flow and the desired temperature can be reached quickly and safely. The steam injector can be easily integrated into an existing pipeline and can be offered with all connection options.

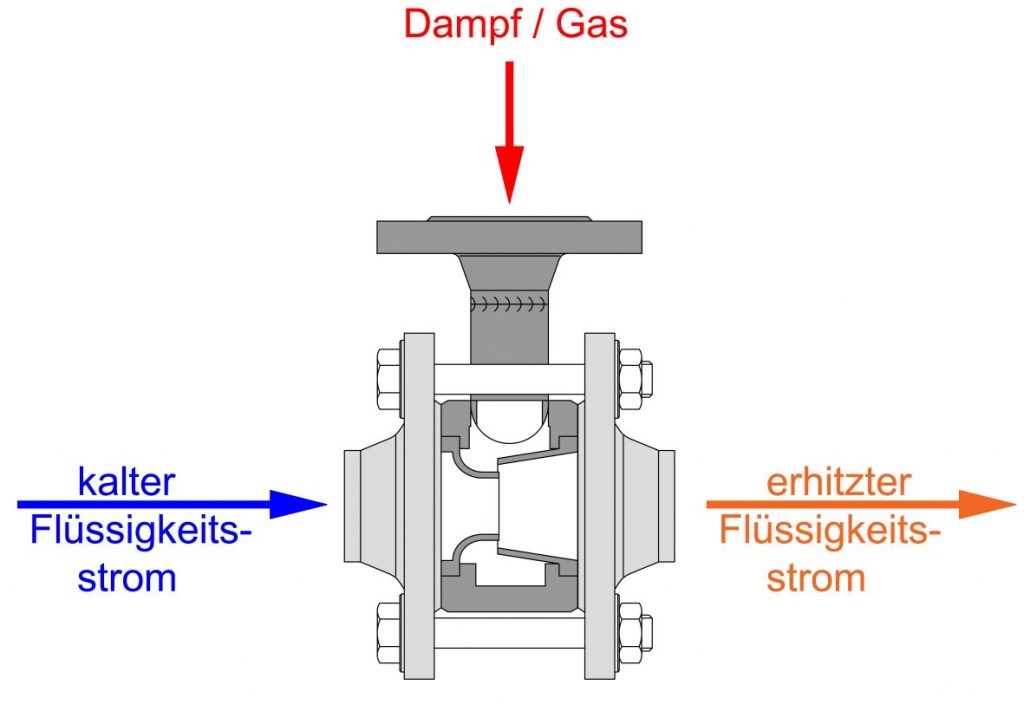

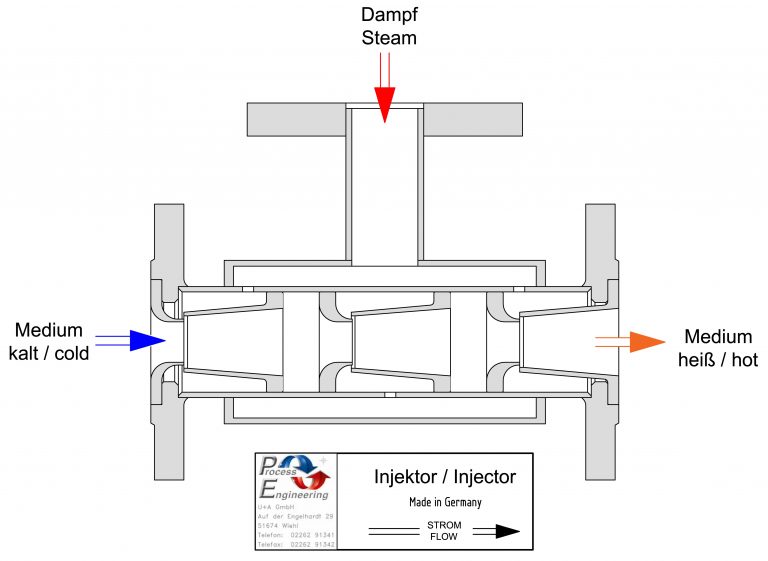

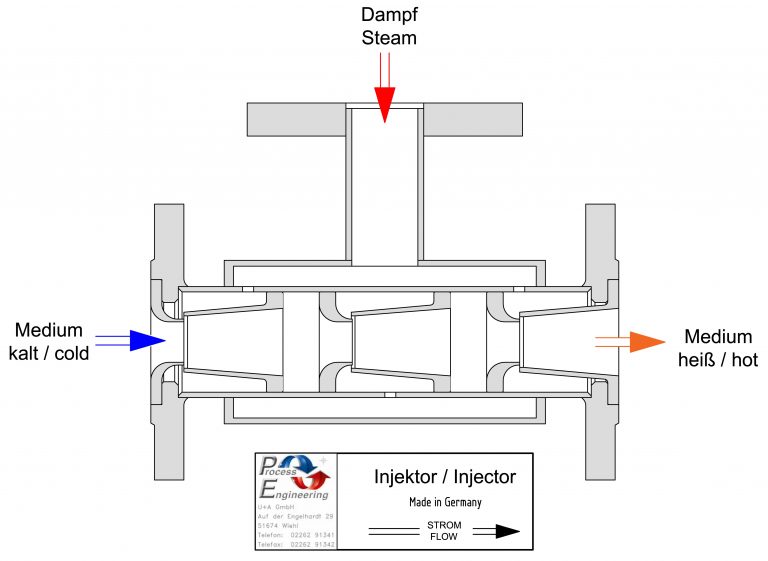

The heart of the U+A injector is a Venturi nozzle in which the medium to be heated is accelerated. A cone formed counterpart is designed in such a way that an annular gap is created. The steam is introduced tangentially into the outer casing, passes through the annular gap onto the medium to be heated and condenses. This condensation ensures even heating, whereby the noises caused by vapor bubble implosions are reduced to a minimum.

The heart of the U+A injector is a Venturi nozzle in which the medium to be heated is accelerated. A cone formed counterpart is designed in such a way that an annular gap is created. The steam is introduced tangentially into the outer casing, passes through the annular gap onto the medium to be heated and condenses. This condensation ensures even heating, whereby the noises caused by vapor bubble implosions are reduced to a minimum.

In this way, a low-noise energy input (normally approx. 75 dB) can be achieved. In general, the amount of steam can be regulated from 0 – 100%. Maximum heat transfer with a small size and investment costs is achieved in this way.

• No moving parts

• Low maintenance

• Can be easily retrofitted in existing systems

• Can be installed in almost all environments

• Quick and easy commissioning

• low-noise steam supply

• Steam quantities adjustable 0 – 100%

• maximum heat transfer

• minimal pressure loss

• favorable installation dimensions

• Any installation position

• Can also be used inside containers with a stirrer effect

• Long service life with a suitable choice of material

• Can be made from a wide variety of materials

• Relatively low acquisition costs

• Simple and reliable

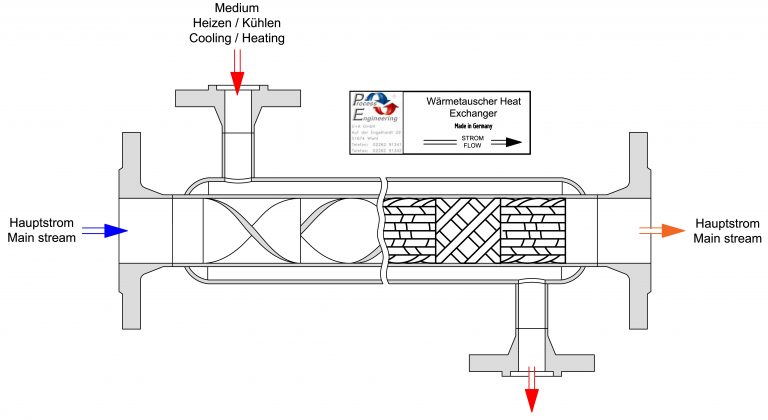

Further possible uses of our injectors are the hot water station for rapid heating of a product stream in the pipeline in one pass and the installation as a liquid jet mixer into a container.

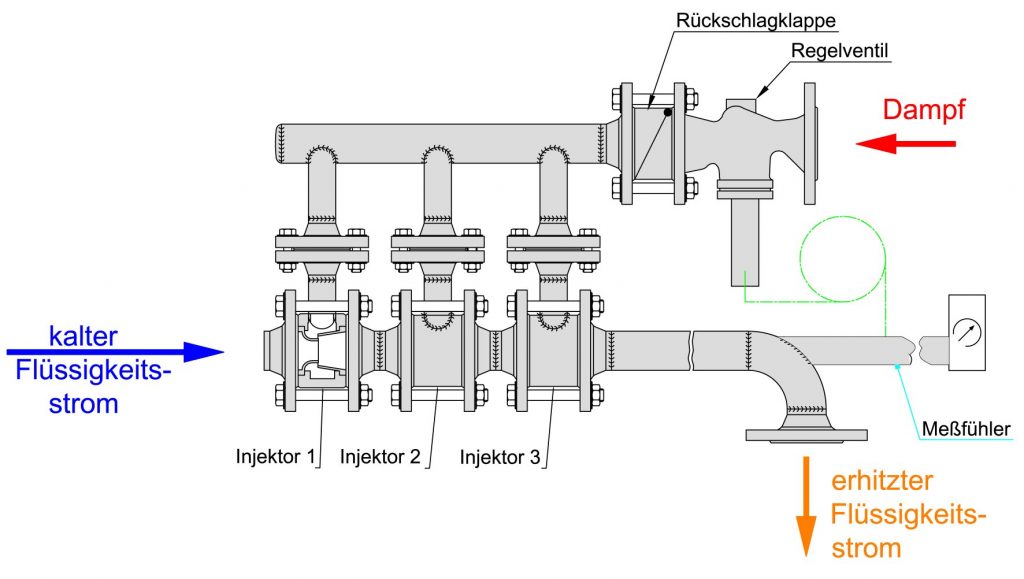

Our hot water station is recommended wherever a product flow in a pipeline needs to be heated as much as possible within the shortest possible time.

U + A offers these customer-specific with a defined scope of services and complete control equipment with and without auxiliary energy.

The hot water station consists of several steam injectors, a control thermostat, a control valve with or without auxiliary energy as well as the necessary connections.

The hot water station is available as a complete unit up to a nominal diameter of 250 mm, but custom-made products are possible.

After being installed in the system, the assembly without auxiliary energy works completely independently and does not depend on an external energy supply.

Despite the designation “hot water station”, of course other suitable media can also be heated. The number and size of the steam injectors is determined individually depending on the requirements with regard to the flow rate and the temperature to be achieved.

By connecting the hot water station to the control device, the temperature to be reached can be set precisely, up to approx 220°C.

The version without auxiliary energy results in further advantages, since the control thermostat and the control valve work without auxiliary energy, there is no risk of influencing the measured values, for example through voltage peaks. There is also no need for expensive and, especially at high temperatures, susceptible cabling to control cabinets.

Cast materials and stainless steels are used for the control device. The steam injectors are made of steel or stainless steel. Other materials, such as Hasteloy, PTFE and nickel can be used if necessary. For abrasive media, the trim can be enamelled or provided with particularly suitable special coatings.

Due to the low follow-up costs, investments in steam injectors or hot water stations pay for themselves much faster than other methods.

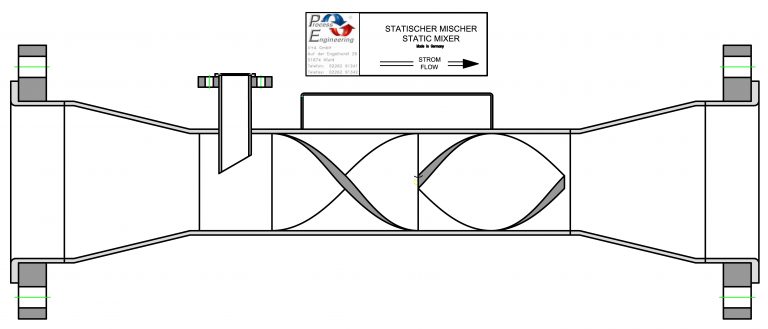

U+A special injector solutions for the container, to heat up liquids cost-effective.

A distinction is made between two installation variants, on the one hand an installation directly in the tank wall and on the other hand as an injector construction with assembly on the tank bottom in a circular formation.

U+A Injectors work as a blasting device and, with an additional agitator effect, evenly heat the contents of the container.

The heart of the U+A injector is a Venturi nozzle in which the flow of liquid is accelerated by steam. The mixture emerging from the injector spreads out in a conical shape and pulls further liquid with it from its surroundings. With an optimal arrangement of one or more injectors, a three-dimensional flow is created in the container, which mixes the entire contents of the container homogeneously and heats it up at the same time.

In general, the amount of steam can be regulated from 0 – 100% using the steam regulator. The size and the required number of steam injectors are designed for the respective application. It depends on the time available to reach a certain temperature.

U+A also offers this solution as a complete solution with a container, a defined scope of services and a complete control system.

Alternatively, the enquiry form can be downloaded as a PDF.

Alternativ kann das Anfrageformular als PDF heruntergeladen werden.

Alternatively, the enquiry form can be downloaded as a PDF.

Alternatively, the enquiry form can be downloaded as a PDF.